It’s been a full week since I had initially charged the CitiCar lithium batteries with an inverter connected to the old lead acid batteries. The lead acid batteries were drained just below 12 volts after three hours of charge.

After seven days of charging, the battery bank has been restored to being fully charged. The 200 watts of solar panels were not even producing 60 watts at peak sunlight in the middle of winter.

The batteries were not recovering much during the day. After a couple days, I added a 4 amp car battery charger/maintainer to continue the charge during the night, rainy days, and when there wasn’t much power from the sun.

At this moment, I’m not fully running on the power of the sun. Even though I may have a large battery bank, it’s problematic if it takes a few days to recover on the sun alone. My goal is to get this battery bank to charge with one day of sun power. I’m under the impression that would need to capture around 3.6 kWh in one day.

I found a Casio online calculator that gave me an idea of having roughly seven sunshine hours this time of year in my location. I would need panels that produce an average of 514 watts throughout the day. The actual wattage of solar panels needed to produce 500 watts at this time of year feels like 2 or 3 kilowatts when looking at my amorphous panels only producing a quarter of what they are rated for, and in a much smaller window than seven hours.

I ordered 500 watts of polycrystalline panels along with another charge controller. I’ll need to look into having a small shed setup in the back yard to mount the panels to the roof.

From what I understand, you shouldn’t mix and match solar panels wired up to your charge controller. However, you can hook up multiple charge controllers to the same battery bank – and you don’t need to wire them up to talk to each other either. I’ll be experimenting with this to make use of the 700 watts I’ll have in total.

Temperature Tantrum

Still puzzled over the noise with the temperature probe, I started doing a bit more reading and experimenting.

I was trying to figure out if there was a specific area a temperature probe should be. I had assumed to put it in the center of the battery bank, dangling halfway above the floor and the top of the battery. I found an exchange of messages on one forum where someone replied that it should be in the center of mass. I also found an article describing that most battery temperature probes are under the battery where the battery heats up the most. I decided to prop the batteries up a little and stick the probe underneath. This helped, but only a little.

I started looking into ways to shield the cable. I put some extra non-conductive toolbox liner under the probe and its wires. This had a significant impact. It was still noisy, so I tried adding another layer under the wires. I had even more success. Next I tried covering the wires from the top as well, but I couldn’t see any significant impact.

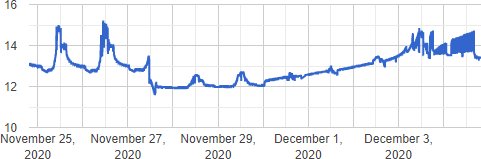

I noticed that the battery charger dropped it’s voltage this afternoon, and is reporting that the battery bank is now fully charged. The chart for voltage is now showing a range of 0.2 instead of 2 volts. This in turn, magnified some “noise” on the voltage chart as well.

Probing

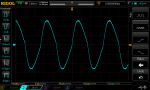

I decided to take a deeper look with the oscilloscope. Probing the most positive battery terminal, I saw a pure sign wave. Probing the positive screw terminal of the temperature sensor revealed the same sign wave. The sign wave went away when the charger was unplugged.

I had my answer. There was simply nothing I could do about it other than to stop using the charger if I wanted a clean reading. Looking at the charger itself, It’s actually labeled rite there below the voltage reading:

High frequency battery charger/maintainer

Conclusion

Although it appears as if I have noise on the line, it’s actually a high frequency sign wave of voltage supplied by the charge controller. Since I’m reading the temperature from the charge controller only once a minute, it will seemingly give a random value between the sign waves highest and lowest peak.

What really stumped me was that two temperatures are always the same – Battery and Remote Battery. When the charger is on, they have different values. This tells me that the frequency is so high that the charge controller itself is requesting these two values from the probe, and that the voltage dropped/raised so quickly that the second check (microseconds later) is out of sync.