I’ve got a real sense of pride and accomplishment now that the CitiCar is able to drive out on the open road again. I’ve taken it on a few test drives, and I’ve ran into a few issues.

The biggest risk of failure is when there is a change – no matter how small. Hold my beer… I just replaced the entire powertrain with equipment that I was unfamiliar with.

The most notable issue is that the car felt like it lost power quite often. It was a bit annoying having to coast to a safe spot to pull over and diagnose what was happening.

The beginning

Teddy and I went on a test drive into town. We had a great time visiting C&C Frozen Treats, I want Candy, and eating ice cream at the town square. We headed over to McDonalds for a bite to eat and then headed towards home.

It first started where I pressed the throttle and the motor would jolt and turn off. After doing this a few times, I slowly pressed the throttle and was able to continue to drive. I suspected that the motor controller was implementing a fail safe to make sure the throttle high-pedal was off before the resistance changed on the potentiometer, and that there was some kind of race condition. As the CitiCar continued to have trouble a little later, I would keep trying to ease my foot lightly onto the throttle.

No Power

Finally, the motor wouldn’t turn on at all and I ended up coasting into the Knotty Pine restaurants parking lot. I was at a loss. I couldn’t figure out what was going on. I had power for everything else. I could hear the contactors activating when shifting between forward and reverse. I pressed the throttle lightly and heard the main contactor activate. “It’s back!” I thought. My next hypothesis was that maybe there was some kind of additional fail safe where the controller would lock me out of operating it for a couple minutes to protect itself.

Paranoia

Continuing on, I was praying I could get home without calling a tow truck. I was going up hill. I decided to play it safe and take a side street, still going up hill and… I lost power again. Here I was, slowing down going up a hill, and someone was behind me. I was almost at a dead stop when the car drove around me. I was a bit paranoid when I recognized the markings of a police car.

I couldn’t go up hill, so I coasted backwards into a driveway and put on the emergency brake. I was trying to figure out the problem in case the officer came back around to check in on how I was doing. I was there for roughly five minutes, certain that I was stranded. It came back alive and I was off, praying I could get back home.

EV at the Gas Station

I didn’t make it far. As soon as I turned onto the main road, I lost power. I coasted into the new gas station parking lot and just barely got into a nice parking spot. I figured if I was going to be there for awhile, I could grab a bite to eat. The person in the vehicle next to me asked if he could take a photo of the car. We talked a bit and I showed him around the car.

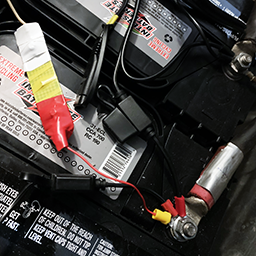

I broke out some alligator clips and a multi-meter and started testing connections. I traced the problem down to a loose connection on the throttle high-pedal contact switch. The wire had almost come off. I pushed it back and it was good to go.

I started to approach the exit and realized the speedometer didn’t have any power. I looked over at the fuse block and saw a light was on. I must have blown the fuse when testing connections with the alligator clips. I pulled off, replaced the fuse, and left the gas station.

Final Stretch

I lost power once more on the way home without much of an area to pull off. I pulled as close to the curb as I could, fixed the issue, and continued on my way.

As I pulled into my subdivision, I was relieved to know that the last half mile was just coasting home. That was the roughest trips I’d ever been on in the CitiCar. Taking a closer look, I noticed the switch’s spade was bent a little, and there was no slack on the wire connected to it. I created an extension wire to add some slack. I noticed the connection felt loose, but I thought nothing of it… until I started running into problems with the next drive.

The Actual Problem

The problem was that the contact switch on the potbox is not as wide as my spade terminals. The female spade terminal was loose and kept falling off.

I ordered an assortment of spade terminals in various sizes. The 4.8mm female connector fit snug onto the switch. I made a few mistakes trying to crimp a non-insulated terminal. I watched a couple of videos and was able to figure it out.

Stalling ICE

I was thinking what would happen if an ICE car did this – and then I realized it does. The first car I owned was a Dodge Colt. My dad matched half of the price. It was a good car, but it was stalling all the time – at stoplights, and even traveling downhill at 90 mph. I was often having trouble trying to start it back up. I knew nothing about cars, but my dad did. I recall he seemed to be close to figuring out the problem. It really stumped him. Eventually the car ended up in a junk yard. I feel as if the CitiCar is much simpler to troubleshoot. Rather than moving parts, vibration, noises, and fumes – it’s just bare-bones simple electronics.

In other news

I’ve changed both diodes on the forwards and reverse shifter from 1 amp (1N4006) to handle 3 amps (1N5408). In addition, it’s legs are thicker and less susceptible to breaking, causing the same experience with no power to the high-pedal – however one direction would still work until the second diode broke.

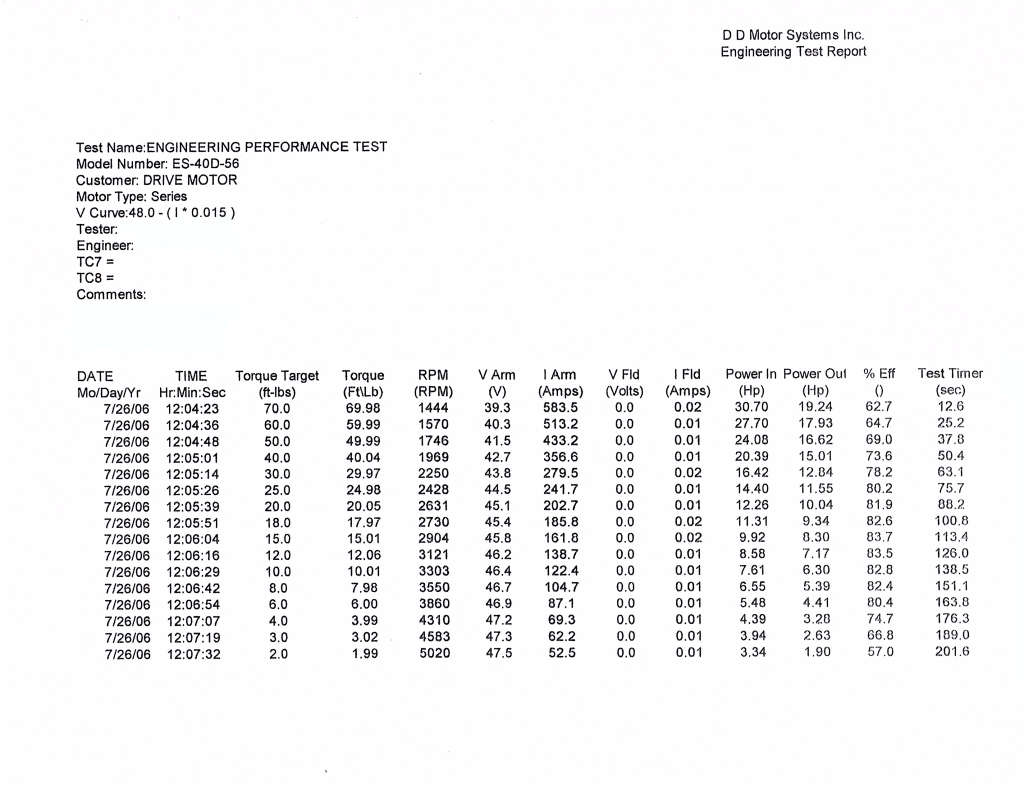

The new D&D Motor Systems motor is about five miles slower than the stock motor from the manufacturer.

I’m looking into other options to track speed without GPS.

I’m looking into installing small lights to work on the car easier and show it off.

I might setup the solar charging station / EVSE this weekend. It can also serve as a backup power supply for power outages.

I’ve been learning about field weakening as a potential option to increase the speed of the motor. From what I gather – 2/3 of original nichrome resistor between S1 & S2 terminals on the body of the motor, use a solenoid to turn it on.